Leak testing machines

Leak testing has been one of our core skills since the founding of the company: Starting in 1966 with the first leak test rig for water pumps, through the classical stroke-step transfer machines up to the current highly complex and highly flexible robotic systems. Automatic checking for leaks in the water cavities, oil cavities and fuel cavities of an engine, is carried out in the leak test rigs. In doing so, the technology developed by JW FROEHLICH enables the desired test data to be quickly and precisely collected and compared with specifications. In the event of the stipulated limit values being exceeded, the leaks are localised on a neighbouring work station and can thus be repaired. Only once the test has been successfully repeated in the production line will the test part be fed back into the assembly process.

In most cases, our systems must be incorporated into a complete processing or assembly line, which requires a great deal of technological flexibility. We develop individual leak testing systems accordingly and create complex sealing elements tailored to customer requirements. Leak test panels developed by our company are installed in our leak test rigs and systems and optimally integrated into the test process.

Leak and function test machines for sealing parts

The combination of test and assembly machines necessitates exceptional professional understanding and expertise in the customers' requirements and maximum precision in the technical implementation in order to guarantee the smooth flow of the parallel or consecutive measurement, testing and assembly processes. Here JW FROEHLICH combines their many years of expertise in the development of assembly machines with their in-depth experience in the design and construction of leak test rigs.

Assembly machines for valve seat rings and valve guides

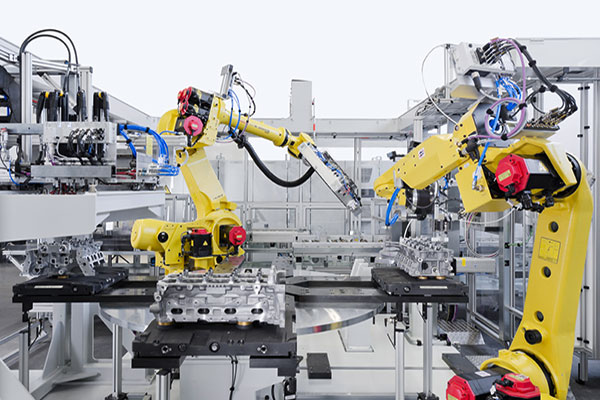

JW FROEHLICH provides assembly machines for valve seat rings and valve guides as flexible assembly centres or as overhead transfer machines. Regardless of the respective version, the assembly machines are always located in the cylinder head processing line to press valve seats and valve guides into the cylinder head after pre-machining. Critical factors for the quality here are the press-in depth of the guides and the exact planar setting of the rings in the blind bores. The assembly parts are oiled during the process as standard. The latest generations also work as gantry machines, whereby the cylinder head is no longer clamped but rather is only held in the mounting position. Here, the cylinder head handling is carried out by a robot in these flexible assembly centres instead of a loading gantry.

Assembly machines for bearing covers

With the assembly of bearing covers, this is an automated process that forms the basis for the subsequent processing of the test part. Accordingly, as with all JW FROEHLICH assembly machines, assembly machines for bearing covers are never located in the actual assembly line, but rather are always in the processing line. In doing so, the focus is on the avoidance of faults and precise assembly within the stipulated cycle time. Control systems and documentation of the process data enable the assembly procedure to be assured. JW FROEHLICH assembly machines are designed to be user-friendly and low-maintenance and impress with their solid and reliable construction.