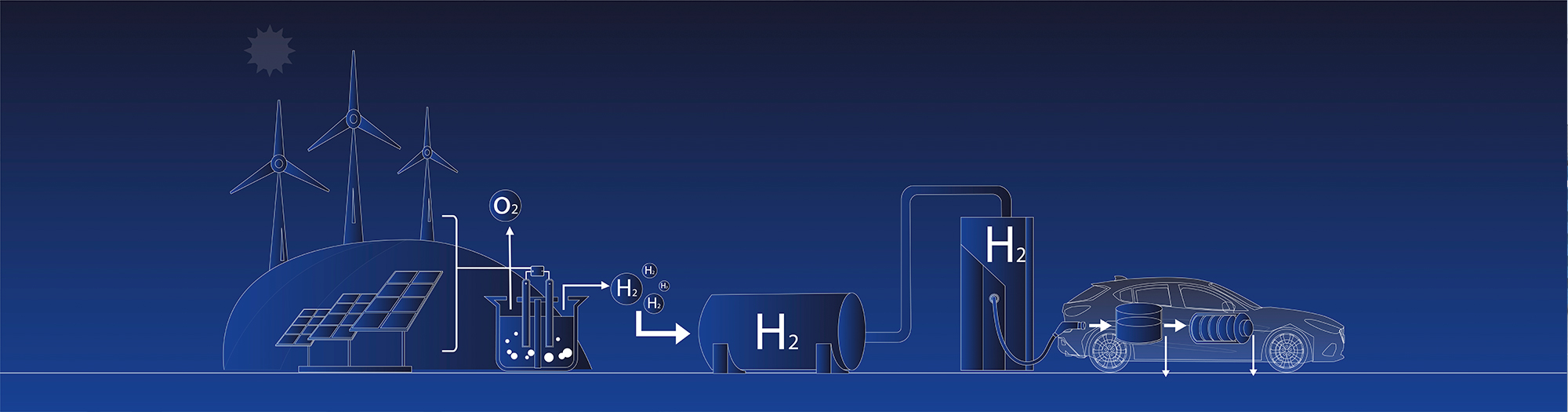

Fuel Cell

JW Froehlich develops user-oriented laboratory and series test stands for testing fuel cell stacks and systems, as well as their components, such as bipolar plates and balance-of-plant components. Anything is possible: from in-line test stands to end-of-line centres, even as a mobile container test system. Longstanding experience with leak tightness and functional testing for the automotive industry meets extensive know-how in automated quality assurance.

JW Froehlich is currently working closely with leading European experts for fuel cells from the Center for Solar Energy and Hydrogen Research Baden-Württemberg (ZSW) in Ulm. A joint development project is the creation of a modular and scalable test system for fuel cell stacks. The federal state of Baden-Württemberg has added this innovation project to its “ZPH2 – Zukunftsprogramm Wasserstoff BW” funding programme.

Tailor-made mapping for fuel cell producers to determine the optimal leak test method for components such as bipolar plates and stacks complete the portfolio.

dicht

- Leak testing with air, nitrogen or helium

- HV tests (voltage resistance, insulation resistance)

- Functional test (operation and testing with hydrogen)

- Leak testing with air, nitrogen or helium

- HV tests (voltage resistance, insulation resistance)

- Functional test (operation and testing with hydrogen)

- Leak testing with air, nitrogen or helium

- Leak testing with air, nitrogen or helium

- HV tests (voltage resistance, insulation resistance)

- Function test

Our test stands and test systems are equipped with leakage test devices developed by our company, which are optimally integrated into the test process.