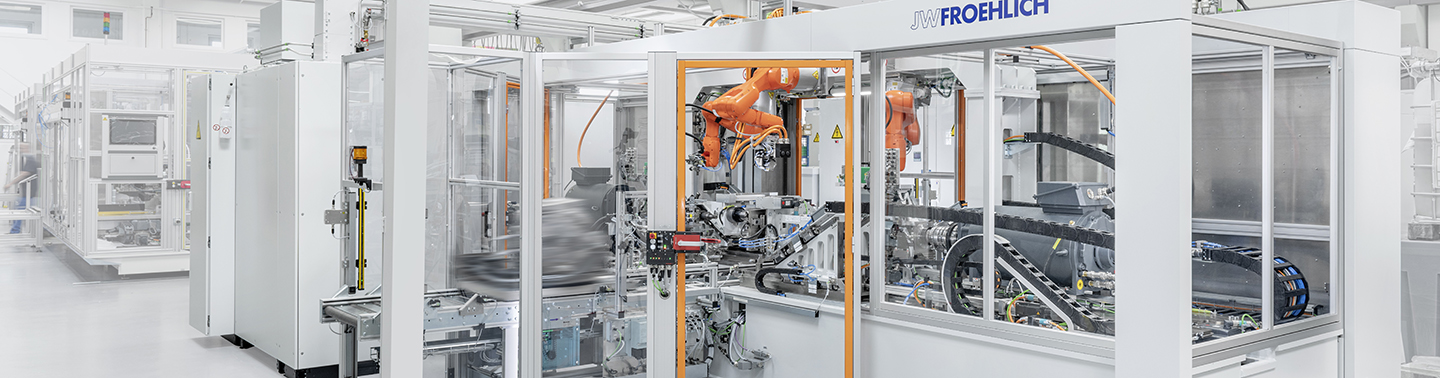

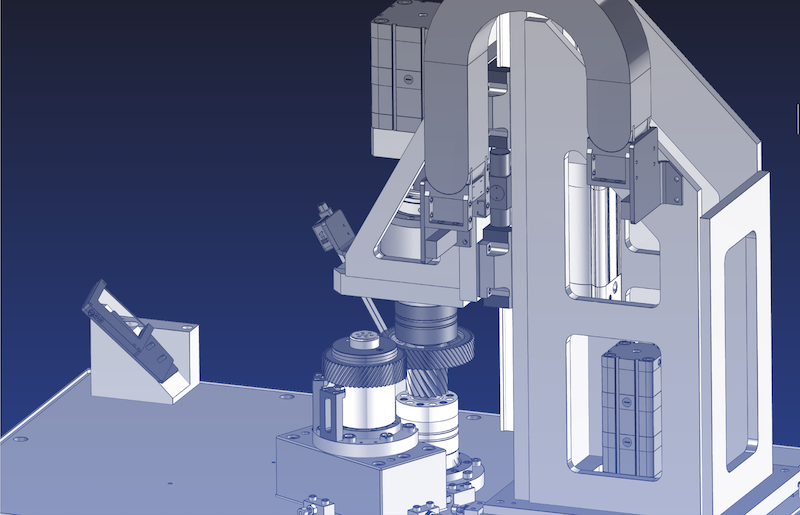

Many automotive manufacturers are increasingly focussing on individual testing of inverters. The heart of an electric vehicle integrates many different functions, and is increasingly manufactured in-house. JW Froehlich’s customized solutions for inverter development and production range from manually set-up development test stands and screening test chambers (for higher loads) to fully automated EOL test stands.

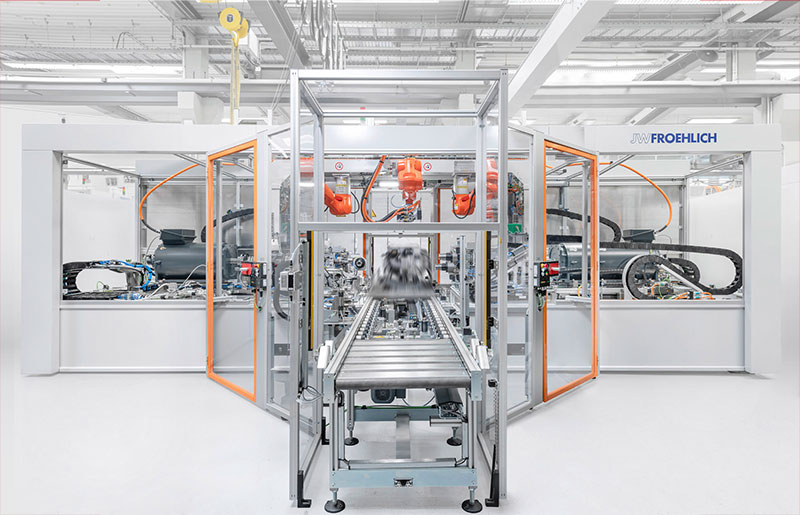

Automation solutions in EOL test stands by JW Froehlich comprise contacting, clamping unit design and test part logistics – depending on the requirements this may include the use of robots. Our internal measurement and testing technology (SOLVISO, SOLCOR) can also be integrated, as can customized solutions. JW Froehlich covers all testing processes – from leak testing and electrical HV testing to functional and load testing.

EOL test stands video