Leak test method

Each test part and each customer has different requirements: We determine the ideal test procedure and the ideal JW Froehlich series of leak test panels and equip these with special functions if necessary, on the basis of the volume of the test part, the desired measurement range and the requirement for operational reliability.

Relative pressure

In the relative pressure method, the test part is pressurised with air and the pressure sensor is used to detect any leakage following the balancing phase. As the pressure sensor is only pressurised on one side, the test pressure which can be applied is limited. The relative pressure method is often used for smaller test volumes and when sufficient test time is available, and is favoured for its cost effectiveness.

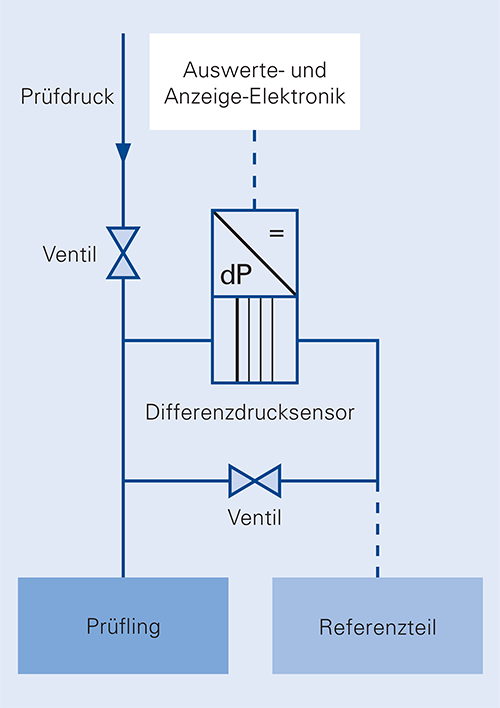

Differential pressure

In the differential pressure method, the test part is pressurised with air and the differential pressure sensor is used to detect any leakage following the balancing phase.

As this sensor is pressurised on two sides, high test pressures of up to 20 bar can be achieved, delivering very fine measurement resolutions. The differential pressure method is thus preferred for high pressures and low allowable leak rates.

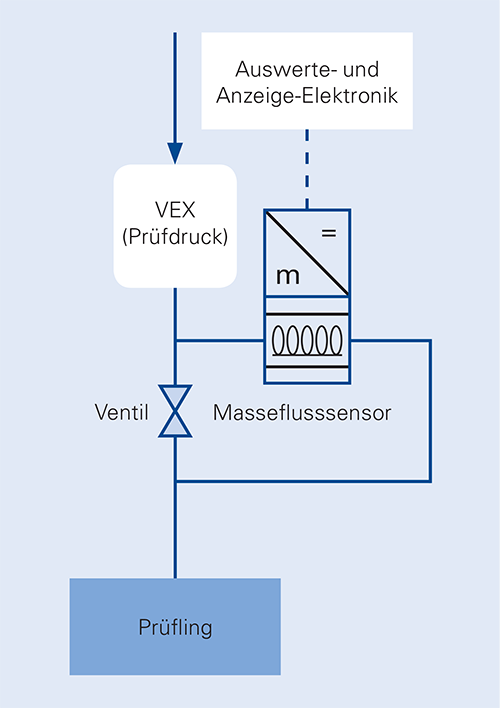

Standard mass flow

The first step of the mass flow method is to fill a reference volume VEX with test air. This is then used to fill the test part and achieve the test pressure. Unlike the pressure decay method, the mass flow sensor delivers immediate measurement results in the event of a leakage, which makes it the most suitable method for high-volume parts and short cycle times. Furthermore, with repeated measurements (MFU), experience tells us that the results of the repeatability accuracy are better.

Features

- Measuring technology for large test volumes from 500 ml

- Instantaneous measuring signals thanks to mass flow sensor

- Shorter test times compared to pressure decay method

- Highly reproducible measurement results

- Measuring signal independent of test volume and test pressure

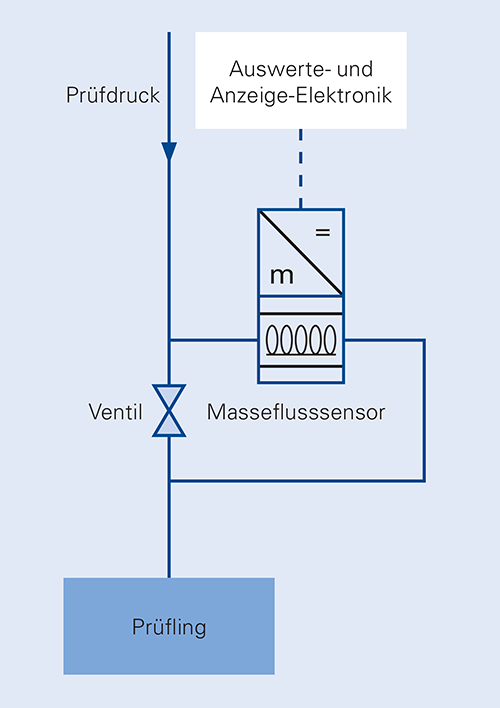

High-range mass flow

With the high-range measurement method, the test pressure is set via a mechanical pressure regulator. The goal is to check high leakages via a constant test pressure. This process is used particularly with test parts with a high leakage whereby the test accuracy and repeatability play a more minor role.