"Noch ganz dicht? Dichtheitsprüfung von Batterien mit Luft und mit Helium", Fachartikel auf www.all-electronics.de

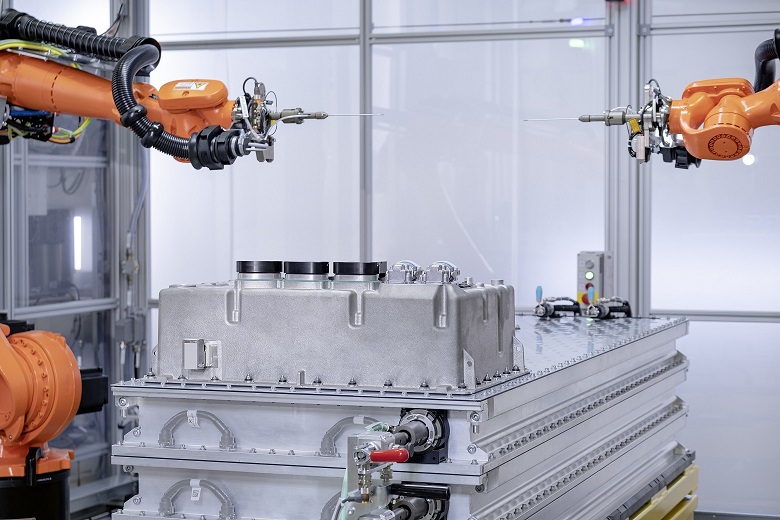

Eine Traktionsbatterie ist im Betrieb rauen Umweltbedingungen ausgesetzt. Deshalb muss sie ausreichend dicht sein. Je nach Anforderung lässt sich die Dichtheit der Batterie entweder mit einem Luftlecktest oder einer Helium-Schnüffelprüfung überprüfen.

read more"Leak test of battery housings", technical article in the yearbook 2022 Dichten. Kleben. Polymer. of ISGATEC

Since there is no standard for batteries today and efficient leak testing depends on many factors, there is also no standard for leak testing. However, if the central challenges are known, suitable testing strategies can be developed quickly.

read more"Procedure for leak testing batteries for e-cars", technical article on www.all-electronics.de

There are several methods for having batteries for e-mobility tested for leaks in an end-of-line test. But which is the right one, which criteria have to be taken into account when choosing and how can the costs for quality assurance be kept as low as possible?

read more"Effectively testing e-mobility components for leaks", technical article in the 2021 ISGATEC yearbook

An introduction to the various thermal management components responsible for cooling the traction battery. In addition, information on possible types of leakage and test methods as well as a discussion of the central question of sufficient tightness for a test object...

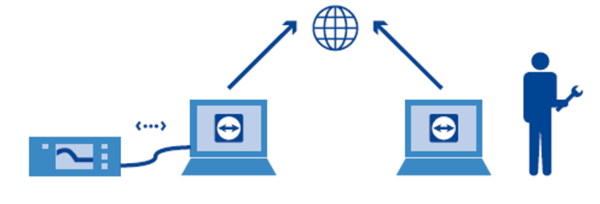

read morePremium Remote Service

In the run-up to the commissioning of leak test panels and during the commissioning itself, there is now special support for machine builders: the Premium Remote Service. Experienced service engineers help to analyse leaky compressed air connections, seals and feeds that would prevent smooth commissioning of the leak tester. Support is provided via remote access - the components required for this are available from JW Froehlich. A fixed hourly quota is included.

read more